Sound describes those mechanical oscillations in acoustics which lie within the audible range of man’s ear. It is the range between abount 10 Hz and 16 kHz. These oscillation spread in solid liquid and gaseous bodies. Noise according to BS661 is sound undesired by recipient and DIN 1320 defines it as disturbing sound.

In modern sound technology a sound baffle is understood as something that ia an obstacle to the spreading out of sound by a reflecting structure. Sound damping material is sound absorption, i.e. its convert into heat. The first case deals with damming, the second with attenuation.

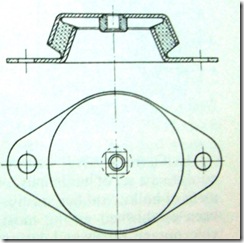

Rubber materials act as effective sound barriers. The aim of sound damping material is to prevent the sound produced by a machine from spreading further, i.e. sound isolation. Also, transmitted reflected sound originating from orther bodies in thus obstructed. The grade of sound damping material is mostly judged with the help of sound meters. Thus the noise strength is measured before and after isolation. The sound strength is plotted for the individual frequencies of which the noise consists.

The processes involed in the damming of the sound which is being propagated through a body are truly complicated. To this day there are no extensive general references which would enable the designer to calculate the effectiveness of a given rubber material barrier. The problems occurring in this field up to the present have had to be handle purely empirically. It has been shown that each dynamically solved rubber damping also carries with it appreciable sound damming. A survey of the incidence of loudness is given in table 1 . For the inportance of sound damming in the framework of sound damping material. The ability of rubber to dam sound is proved by the slowness with which the sound is propagated. (Sound propagation in rubber is approximately 1/70 that in steel.)

Relate topic

Sound isolated piping

Table 1 Order of magnitude of sound volumes

| Phon | Volume of sound |

| 10 | very soft whisper |

| 20 | slight rustle of leaves |

| 30 | ticking of a clock |

| 50 | normal conversation |

| 60 | vacuum cleaner noise |

| 70 | telephone ring, desk apparatus at 1 m distance |

| 80 | very busy road |

| 90 | machine shop with lathe and automatics |

| 100 | noise in a cotton and silk weaving shop |

| 110 | pneumatic riveters in a boiler shop |

| 120 | peening of welds with pneumatic hammers at 2 m distance |

| 130 | pain threshold, sound effect at the operator’s head during peening with pneumatic hammers |

|

|