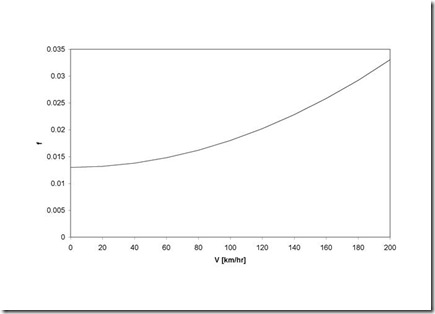

The rolling resistance coefficient f generally increases with the speed V of the vehicle , at the beginning very slowly and then at an increased rate. The following expressions can be used

f = fo + KV

or

f = fo + KV^2

The value of fo and K must be measured on any particular tire . The speed at which the curve f(V) show a sharp bend upward is generally said to be the “critical speed of the tire” (Pic1) the critical speed is influenced by many parameter such as above that speed strong overheating take place; as most of increase of the rolling power is converted into heat. the increase of temperature can quickly cause the destruction of the tire itself ; the standing waves which propergate along the circumference of the tire from the contact zone are clearly visible. And it is of the factor which must be taken into account in the choice of the tire.